Single 1 Cavity Aluminium Foil Container Mould

1. Features

1. Moulds are built with high quality steel. Flow area is heat treated for proper hardness, which ensure our mould in long life.

2. Moulds adopts pneumatic rebound device which makes the mould more flexible.

3. Our excellent processing technical ensure that the mould can complete the cutting, shaping, blanding and curing by one step.

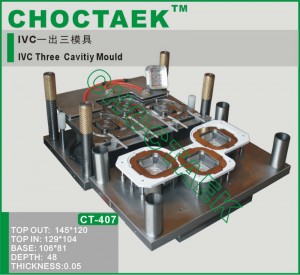

we can design and produce specially all kinds of aluminum container moulds such as single cavity or multi- cavity mould, moulds for the production of various containers with different rims (G style, L style, IVC or Folded style)

2. Innovation

CHOCTAEK develops the Zero- webless mould, depends on customers' requirement. Zero- webless design can save the cost for customers.

High quality, Good design, Innovative technology, High productivity, that is what CHOCTAEK (we) would like to offer to customers.

| Working speed | 50-60 times/ min |

| Container’s size | Depending on the customer’s requirement |

| Material | Iron |

| Max. Foil Width | Depending on the container’s size |

| Thickness | according to the requirement (0.035-0.2mm) |

| Warranty period | 12 Months |

| Cavities | One cavity |

| Container’s type | Wrinkle wall container |

| Machine’s type | 45/ 60/ 80T |

| Delivery Date | 50- 60days |

| Raw Material | 3003- H24, 8011- H22 |

3. CHOCTAEK ADVANTAGE

1. We use the best raw material in China such as Cr12MOV and 45# Steel, it will ensure the mould performance keep good for more than 10 years.Attaching the good comments from customer about our mould.

2. We will do the Special heat treatment processing on spare part of mould to increase the mould hardness. ( such as curling part,male&female die, and so on)

3. The wasting foil scrap of our mould is about 12%- 15% ,even less, it could save your cost.

4. Othe products

Aluminium Foil Container Maing Machine

1. Our machine is the Full automatic machine it will require less labour. ( e.g., one of our Saudi Arabia customer have 8 sets of full automatic machine, with one technician and 8 persons to pack the container can keep the whole factory work smoothly.) it will save your labour cost.

2. We use the SIEMENS PLC, It is easy to operate. SIEMENS PLC has memorable function. Once you input the mould procedure data, save it and remark the item code, you will find it any time, it will save your time to re-set the mould in the next time, thus improve the machine efficiency.

3. Our machine is very safey. The machine will stopped when the safe door opened or the blowing out sensor on stacker detect no container comes out. It will protect the machine, mould & workers together. It also can keep the machine and mould for long life.

Please feel free to call us when you are interested in Aluminium Foil Container Making Machine and Mould project.

E-mail: essia@choctaek.com

WhatsApp:0086 18927205885