Wholesale China Aluminum Container Machine Companies Factory - Automatic Aluminium Foil Container Production Line With 3 Cavities Mould – Choctaek

Wholesale China Aluminum Container Machine Companies Factory - Automatic Aluminium Foil Container Production Line With 3 Cavities Mould – Choctaek Detail:

1. Features of Product

2. Product introduction

Our stacker can collect, count, remember, stack and unload aluminium foil container automatically and independently. The width of the stacker can be regulated according to the container size. It is possible to stack containers of different dimensions. The stacker is suitable to stack all container in different shape.

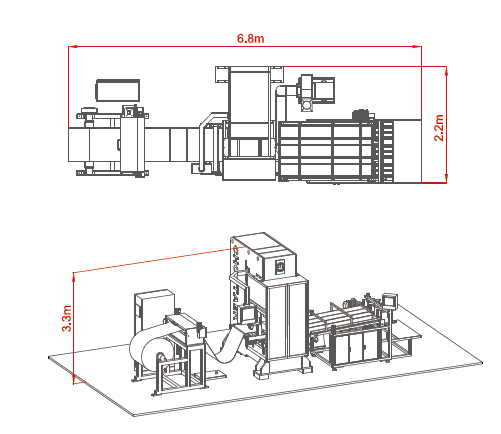

3. Position of production line

4. 60T Aluminium Foil Container Making Machine Parameter

| Strokes | 35-65 times/min |

| Total weight | 6.3Ton |

| Motor Capacity | 9KW |

| Voltage | 3-380V/50HZ/ 4 Wires |

| Press Dimension | 1.2*1.8*3.3M |

| Expansion Shaft | Φ3 inch/6 inch |

| Max. Foil Roll Out Dia | Φ700mm |

| Max. Foil Width | 800mm |

| Length of Stroke | 220mm(custom-made 200/250/280mm) |

| Working Table Dimension | 1000*1000mm |

| Max. Mould Dimension | 900*900mm |

| Mould Closed Height | 370-450mm |

| Slide Area Dimension | 320*145 4-Φ18 |

| 320*245 4-Φ18 | |

| The Whole Production Line Space | 8*3*3.4M |

| Air Consumption | 320NT/min |

C1000, the complete equipment includes: decoiler, control panel, press, stacker, scrap foil collection system etc.

Configured with electronic components imported from famous brands like Siemens, Schneider etc., the whole machines adopt advanced designs and perfect processes, which are equipped with advanced intelligent systems to realize the whole machine linkage control.

C1000 is currently the most advanced aluminium foil container making machines in China, well known for their high degree of automation, less failure, safety and steadiness, high efficiency and easy operation.

5. FAQ

1. Q: What is number of the Max. Mould cavities?

A: It depends on the container size and shape. Such as 450ml, the Max. Mould cavities is 3 on C1000 aluminium foil tray machine.

2. Q: What is the capacity?

A: It depends on the container size and shape. Such as 450ml, the capacity is about 45pcs/minute*3mould cavities= 135PCS.

Please feel free to call Ms Essia when you are interested in Aluminium Foil Container Making Machine and Mould project.

E-mail: info@choctaek.com

WhatsApp:0086 18927205885

Skype:essialvkf

Product detail pictures:

Related Product Guide:

High quality Very first,and Shopper Supreme is our guideline to offer the most beneficial company to our clients.Nowadays, we're hoping our best to be certainly one of the top exporters in our area to satisfy consumers additional will need for Wholesale China Aluminum Container Machine Companies Factory - Automatic Aluminium Foil Container Production Line With 3 Cavities Mould – Choctaek , The product will supply to all over the world, such as: Oslo, Southampton, Bhutan, With many years good service and development, we've a professional international trade sales team. Our products have exported to North America, Europe, Japan, Korea, Australia, New Zealand, Russia and other countries. Looking forward to build up a good and long term cooperation with you in coming future!

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!