aluminum foil cover/cap/lid punching making machine

1. Product introduction

1.1. This production line can work automatically. Worker control and regulate this production line through electric control equipment.

1.2. The width of decoiler is about 750mm.

1.3. The feeding system control feeding length and stepping by computer, which assure a high- precision steps.

1.4. We can design and manufacture different machines on request. There is some difference in machine’s outer-appearance.

1.5. The press may be equipped with single cavity or multi- cavity moulds for wrinkle- wall or smooth- wall container production.

The working flow of aluminum foil machine 60T:

Aluminum foil roll - decoiler- air output control equipment- 60T pneumatic press- mould- auto-stacker or conveyor- collection desk- packing

2. Fully automatic aluminium foil container machine 60T Parameter

| Strokes | 40-65 times/min |

| Total weight | 6.3Ton |

| Motor Capacity | 9KW |

| Voltage | 3-380V |

| Press dimension | 1.2*1.8*3.3mm |

| Expansion shaft | 3 inch/ 6 inch |

| Length of strokes | 220mm |

| Working table dimension | 1000*1000mm |

| Slide area dimension | 320*145mm |

| Space | 10*4*4.5M |

| Motor | Siemens |

| Sensor | Sick |

3. Company History

April,2003: CHOCATEK was founded;

August, 2005: Opened the overseas market;

October,2008: Business was developed and enlarged our factory scale;

April,2010: Established the first full-auto container machine in China;

July, 2012: Applied lots of patents for new technology;

March,2013: Expanded the global market and enlarged our factory scale again

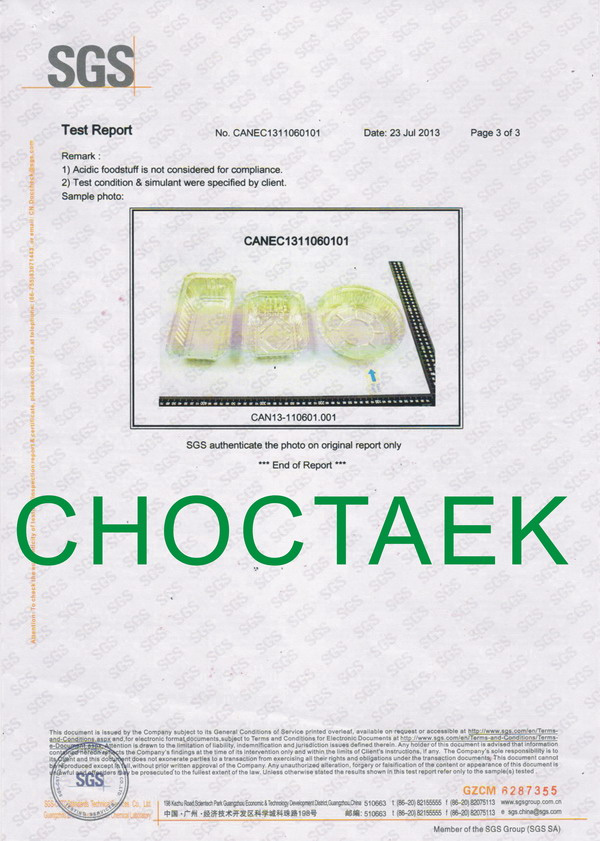

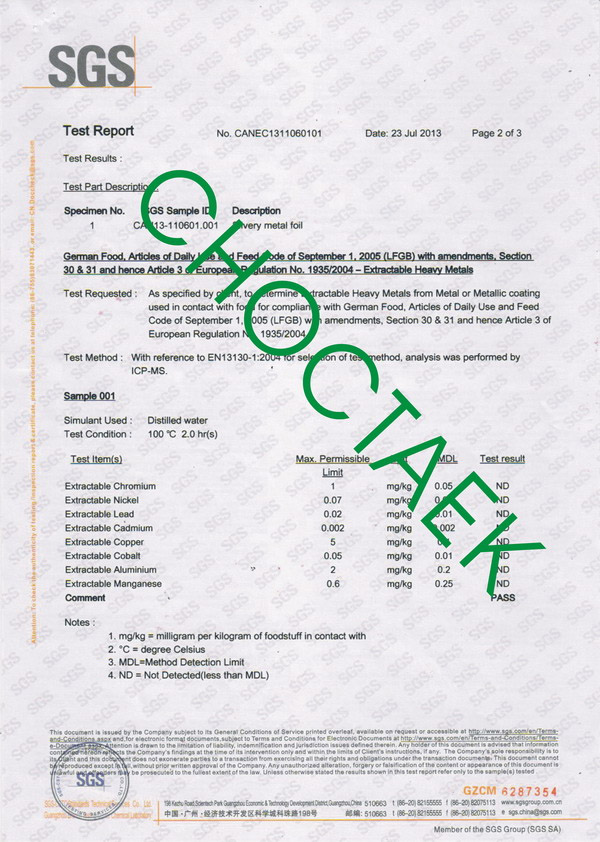

4. Certifications

5. FAQ

1. Q: What is the difference of full automatic and semi automatic?

A: Full automatic collect and calculate the container by stacker automaticly, BUT semi automatic collect and calculate the container by manual, the semi conveyor instead of stacker.

2. Q: What is the raw material?

A: 3003- H24, 8011- H22 for wrinkle wall aluminium foil container.

8011- HO for smooth wall aluminium foil container.

3. Q: What is the thickness?

A: thickness from 0.035- 0.3mm is workable on our aluminium foil container making machine and mould.

4. Q: What is the delivery date?

A: 45- 50days for the machine.

75- 80 days for the wrinkle wall aluminium foil container making mould.

For more questions about our aluminium foil container making machine and mould , please

contact with us:

E-mail: essia@choctaek.com

Phone/ Wechat: 0086-18927205885